Construction lifts or aerial lifts are some of the most versatile and useful equipment on construction sites. Whether there is a need to replace scaffolding or to complete work in hard-to-reach spots, construction lifts are much valued by construction professionals.

Though there is no denial of the utility of a lift for construction work, it is vital to keep in mind major safety concerns. Construction teams can remain safe on their work site by being educated and trained in the risks and common hazards of using construction lifts.

Following are the major construction lift accidents and the ways to avoid them:

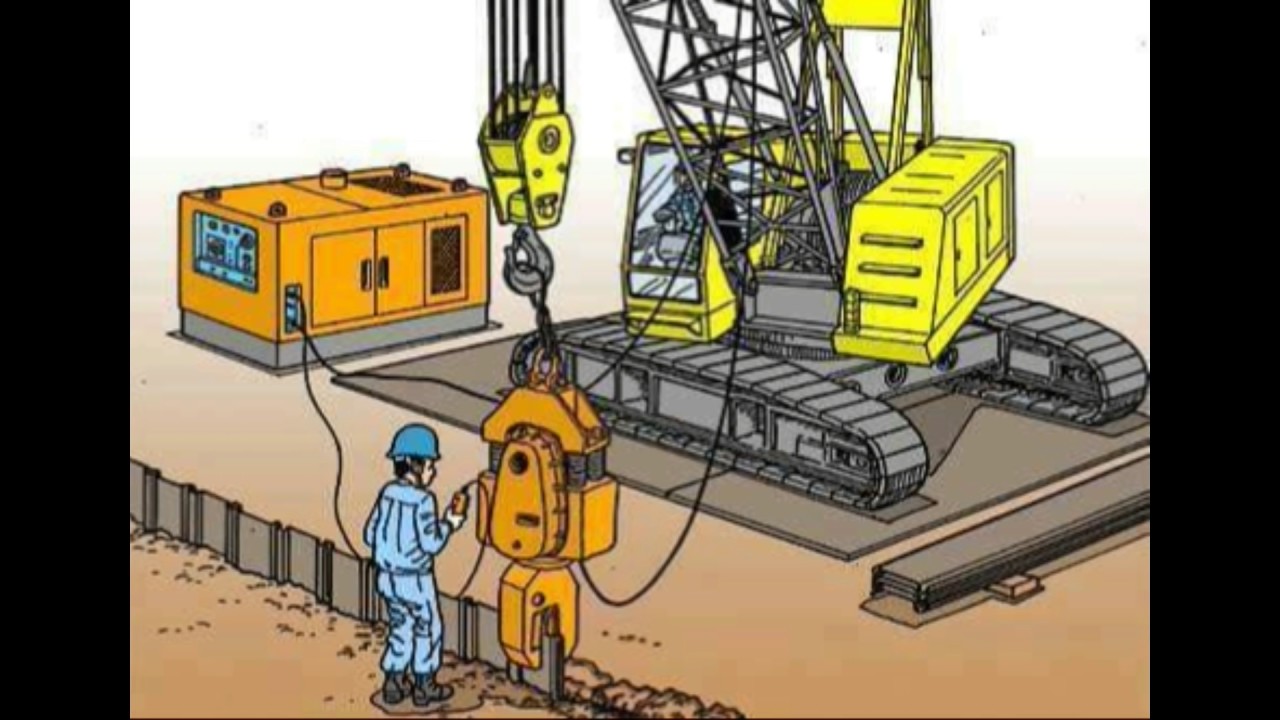

Electrocution of workers

Electrocution is the major contributor to the deaths of construction workers. Electrical safety at a construction site begins with this tenet: always consider overhead power lines as live unless claimed otherwise by a rep of the power company.

Other best practices for this safety include:

- If possible, avoid positioning the lift between overhead power lines.

- At all times, stay away from live power lines at a distance of at least 10 feet.

- Get the power company to shut the power lines down in the work zone prior to beginning work.

- Wear hard hats and insulated clothing, boots and gloves while working near power lines.

- Make use of insulated buckets in proximity to overhead power lines.

- Also, ensure that workers are wearing fall protection equipment to avoid the danger of falls after receiving a shock.

Prevention of falls from lifts

Another leading cause of fatalities of construction workers is falling from heights. They are responsible for one-third of all deaths in this field. Hence, fall protection gear is highly useful for construction lift workers.

Prevention of falls begins with the careful perusal of the worksite to spot any hazards. The latter include unsafe terrain or weather or even nearby vehicles and objects. Therefore, OSHA recommends all construction workers to don fall protection gear. This is as vital a factor as low construction lift price.

Other practices for this include:

- Ensuring that all openings and access gates are closed prior to raising the lift platform into the air.

- Avoid climbing on the guardrails or leaning on them.

- Staying firm on the floor of the lift platform.

- Avoid the use of planks or ladders while stationed on the platform.

Avoiding collapses and tip-overs

Collapses and tip-overs result in many of the deadliest accidents since they can crush persons in construction lifts or the ground. There are many causes of tip-overs. They are:

- Improper handling of lifts

- Careless conduct of pre-start inspections

- Exceeding the maximum load limit of the lift.

- Carrying excessively large objects

- Driving of lift with raised platform

- Exceeding limits of lifts vertically and horizontally

- Operation of lift in inclement weather and strong winds.

For the use of best practices for tip-over safety, always stay within the load limit of the lift at all times. Avoid travelling to the worksite with a raised platform or bucket. Avoid raising the platform while driving on sloping, uneven or soft terrain. Avoid the use of excessive horizontal force in scissor lifts and the raising of the platform in conditions of high wind.

Most collapses of an elevator lift in construction are due to mechanical failure. These can be avoided by detailed pre-start inspections and regular maintenance. Good training helps in the effective conduct of inspections.

In sum, these are the major safety issues related to construction lifts. The best measure is to train all workers in the right safety procedures before undertaking construction work. This may not prevent all accidents but will greatly reduce the risk of these mishaps at your construction site.